34-LINDNER-Waste Wood Fuel

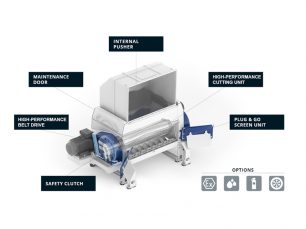

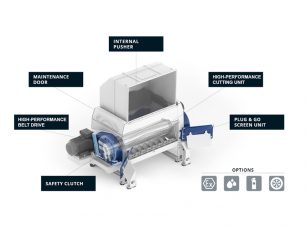

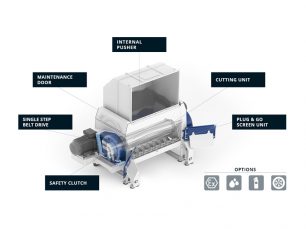

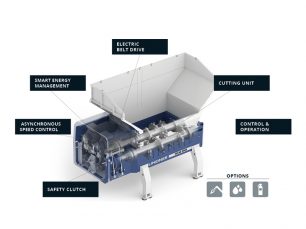

ENERGISER

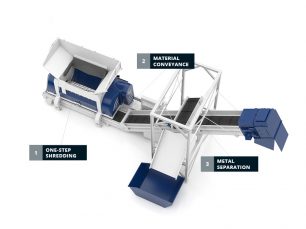

Powerful performance: The perfect combo of a Lindner Urraco or Miura series twin-shaft shredder with a Lindner Zeta Star screen ensure that the heat will always be turned up in thermal power plants. Together, these two guarantee defined particle sizes at impressive throughput rates. The design is, of course, Lindner style: durable, robust and efficient.

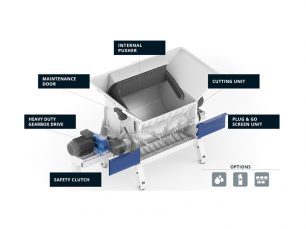

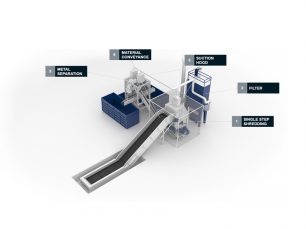

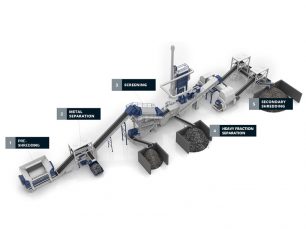

1: SHREDDING

The waste wood is collected in large quantities at the recycling company’s premises and mostly fed directly into the shredder with a wheel loader or a digger. The digger operator first separates the metals etc. during the feeding process. The water spraying system on the shredder makes sure that there is none of the air-born dust usually found while processing wood. The aim here is to shred the material to previously defined output sizes ranging from 80 to 120 mm.

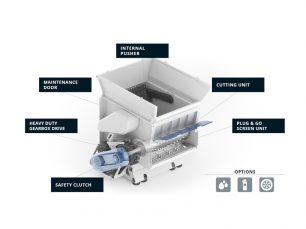

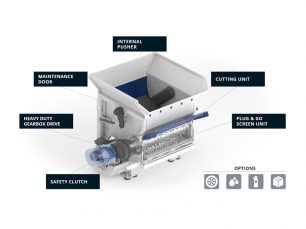

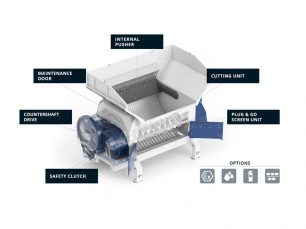

SHREDDER REQUIREMENTS

In single-step waste wood processing it is particularly important that the shredder is able to handle a variety of input materials since waste wood is often very bulky (e.g. large wood panels and broad boards). With its special double-shaft cutting/crushing principle and the aggressive intake necessary for broad and bulky pieces of wood, the URRACO series is the perfect waste wood shredder and with its fully welded shaft system it is the toughest machine for extremely difficult waste wood such as railway sleepers with solid iron sheets.

2: MAGNETIC SEPARATION OF FERROUS METALS

The magnetic separator fitted above the discharge conveyor safely extracts ferromagnetic parts such as nails, metal plates and hinges.

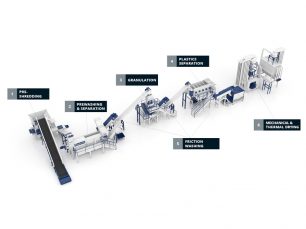

3: SCREENING

After shredding, the final particles are further classified. A defined particle size of usually <80 mm, <120 mm or according to the class in line with EN ISO 17225-1 are required for incineration in combined heat and power plants.

4: RETURNING OVERSIZED PARTICLES

Thanks to an integrated system, the screened out oversized particles are returned to the shredder. This eliminates the need to transport the material back into the shredder with a wheel loader.

TURNING WASTE WOOD INTO FUEL

Waste wood shredding for energy recovery in thermal power plants

Energy recovery from waste wood in large biomass power plants has become very popular and is often the only way to recycle large quantities of waste wood in the grades A1–A4, ranging from pallets to old railway sleepers.

This allows waste wood to be turned into valuable fuel to generate heat and electricity. The recycling process is kept as lean as possible to fuel the power plant with material that has the lowest costs per ton.

WASTE WOOD FUEL CHARACTERISTICS

| Standard | EN ISO 17225 |

| Grain size | 80 — 120 mm (categorised in P classes) |

| Waste wood categories | A1 — A4 |

| Use | as fuel in thermal power plants |

Производитель:

LINDNER

Категория:

Сортировка и переработка отходов

Подкатегория:

Комплексные решения по сортировке и переработке отходов