36-LINDNER — Light Scrap

Metals are precious raw materials that can be recycled and formed new products almost endlessly

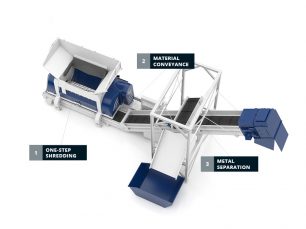

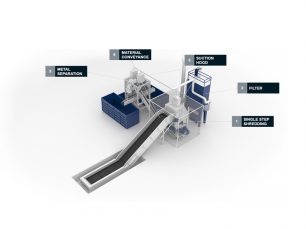

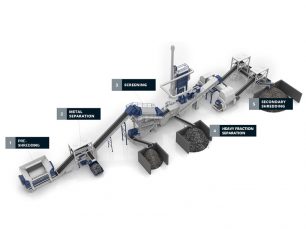

1: SHREDDING

When processing light scrap such as scrap iron, sheet metal, aluminium profiles and electronic scrap, the focus is on the shredder. By definition, metals are very resistant to and abrasive in the shredding process. In this step, partially bulky and long metal parts are transformed into a sortable product with greatly reduced volume. The final output is then either directly recycled in the circular economy or is subjected to further processing including being melted down.

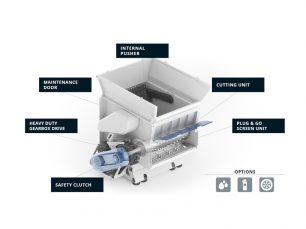

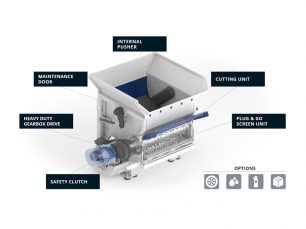

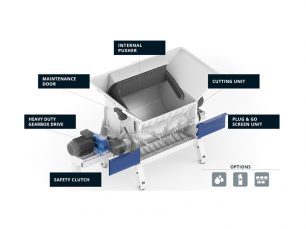

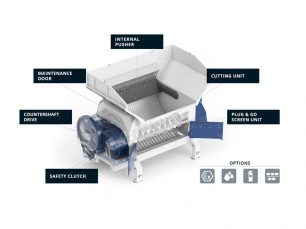

SHREDDER REQUIREMENTS

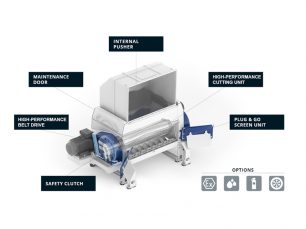

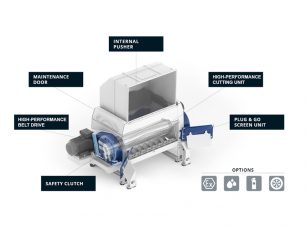

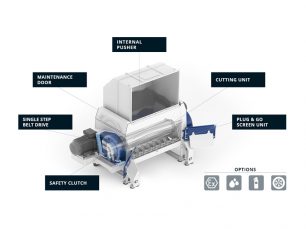

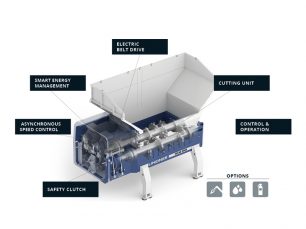

A shredder employed in processing metal must be very sturdy by design. Cutting tools particularly suited to the application – featuring wear and tear-proof hardfacing executed with highly wear-resistant steels – ensure minimum downtime and maximum efficiency during the entire service life. Particularly in this application, our URRACO 95DK with optional hardfacing and enormous shredding power proves its strength to give you high throughput rates.

2: MAGNETIC SEPARATION OF FERROUS METALS

Especially while processing metal profiles or metal frames, over-belt magnets can easily sort out ferrous metals. With this step, higher quality, homogeneous fractions can be achieved (e.g. aluminium scrap).

Производитель:

LINDNER

Категория:

Сортировка и переработка отходов

Подкатегория:

Комплексные решения по сортировке и переработке отходов