32-LINDNER-In-house Recycling

NOTHING TO WASTE

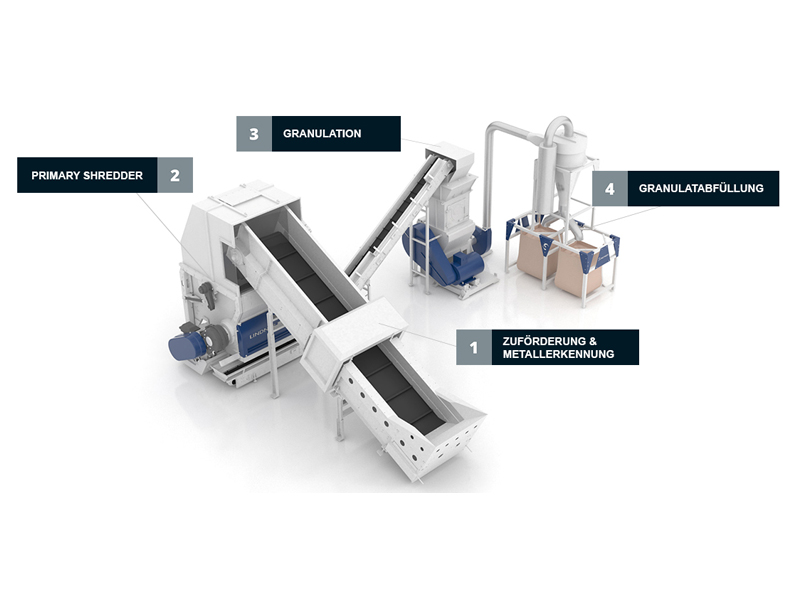

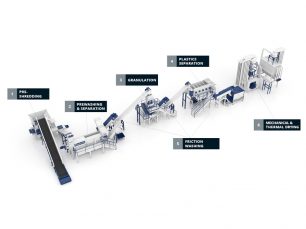

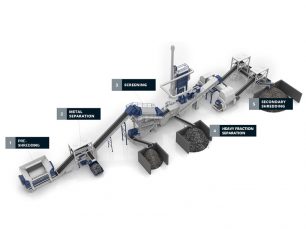

Don’t waste it: With our compact solution combining primary shredder and granulator, it has never been so easy to make plastic waste, defective products or off-cuts ready to re-enter the production cycle. Enjoy maximum productivity with our highly efficient, robust and low-maintenance components.

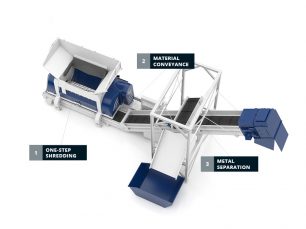

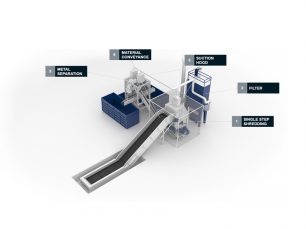

1: FEEDING

In this step, the material is fed into the machine via a conveyor belt. Materials can be supplied to the conveyor belt via a wheel loader or a forklift. To facilitate continuous feeding, our shredders permanently communicate with the conveyor belt and subsequent processes such as granulators or extruders. The metal detection system directly connected to the system control protects subsequent processes. This is necessary to guard the granulator, which is sensitive to foreign matter, and to prevent the high costs caused by downtime.

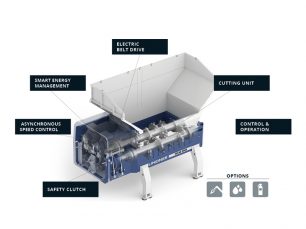

2: SHREDDING

In the second step, the visually inspected material is shredded. The robust Lindner shredder splits the material into the right output size for subsequent processes. To achieve the best possible throughput the shredder, conveyor and granulator continuously communicate and control the speed and the amount processed.

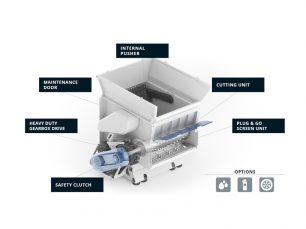

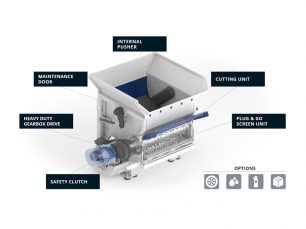

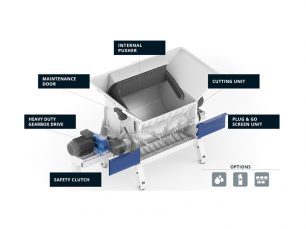

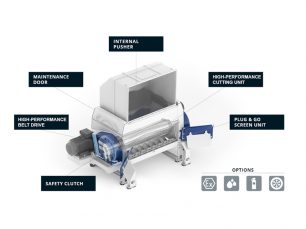

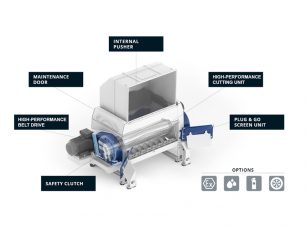

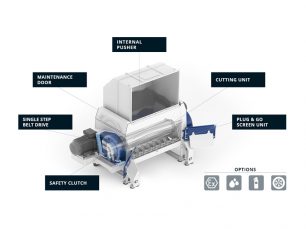

SHREDDER REQUIREMENTS

In this case shredding is considered a protective and efficiency-enhancing measure. During the process, high pressure is used to push the material – in the form of blocks or chunks – against the processing machine’s components. Shredding is necessary to safeguard the high-speed granulator, and the entire process, from downtime. Furthermore, foreign objects might enter the process, and in this way they are easily shredded and subsequently discharged.

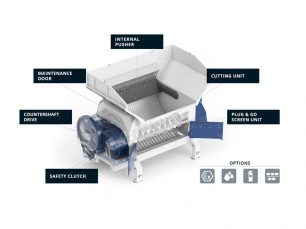

3: GRANULATION

The material coming from the foreign matter-resistant shredder is fed into the granulator and processed to the required particle form. Rotor speeds of 600 rpm are normal in this process. Due to the high speed, it is necessary for the material to be as perfectly prepared as possible to avoid the granulator malfunctioning.

4: GRANULATE COLLECTION

PROCESSING WASTE FROM PLASTICS PRODUCTION

Shredding of plastics waste and rejects ensures efficient recycling

Внутренняя переработка для эффективных производственных процессов – пластиковые и другие производственные отходы являются важным сырьем для производства изделий из пластмасс. Измельчители Lindner были разработаны с учетом именно этих требований. Благодаря регулируемому зазору и переменным сеткам вы можете настроить размер частиц в соответствии с вашими последующими процессами.

Our primary shredders are resistant to foreign objects and are able to shred hard, rigid plastics to a particle size of <10 mm, as is necessary for recycling purposes. Since the material is often bulky and slightly contaminated, it is not possible to feed the material directly into the granulator. That’s were the primary shredder comes in, splitting the materials to protect the granulator or extruder and minimise the costs of downtime.

IN-HOUSE MATERIAL CHARACTERISTICS

| Particle size | < 10 mm |

| Throughput | > 4 t/h |

| Material | PP, PE, PE-HD, PE-LD, PE-LLD, etc. |

Производитель:

LINDNER

Категория:

Сортировка и переработка отходов

Подкатегория:

Комплексные решения по сортировке и переработке отходов